Carried out in lab tests involving small animals, the biomedical breakthrough suggests that the technology may one day provide a means of regenerating complex nerve injuries in humans, making way for the potential personalized treatment of a wide variety of nerve injuries. A paper describing the work appears in the new issue of academic journal Advanced Functional Materials.

Peripheral nerve injuries involve damage to nerves outside of the brain and spinal cord, for example to nerves found in the arms and legs. The result of most of these injuries – from car accident, or battlefield wound – is a gap in either one or more nerve pathways, which disrupts the patient’s sensory and/or motor functions, similar to a severed electrical cord – no full cord, no communication.

“The gold standard for regeneration of nerve injuries which contain a nerve gap involves autologous grafts which consist of sacrificial nerve tissue harvested from elsewhere in a patient’s body,” said Johnson. “However, such approaches unfortunately involve additional surgery and potential chronic pain at the donor site.”

Efforts to address these limitations have recently led the team to explore alternative technologies such as 3-D printing for the fabrication of hollow, tissue scaffolds, known as nerve guides, for peripheral nerve regeneration. “Although highly useful in regenerating linear nerve gaps,” said Johnson, “traditional manufacturing approaches associated with the fabrication of conventional nerve guide technologies have primarily provided basic geometries, such as linear tubes.”

This is where the team’s work stands out. Using 3-D imaging technology known as structured light scanning to first reverse engineer a subject’s nerve structure, the team then had access to the geometry of the nerve pathway in a computational environment. With this geometric information, the group subsequently created customized anatomical scaffolds using 3-D printers.

Previously challenging, the breakthrough enables the fabrication of conduits for complex nerve injuries, such as gaps in bifurcating nerves, as well as multi-channel nerve guides which support the regeneration of sensory and motor nerves.

The team was composed of industrial, mechanical, and biomedical engineers and molecular biologists from Virginia Tech, Princeton University, Johns Hopkins University, and the University of Minnesota.

Although testing in humans is still at least 5 to 10 years away, Johnson said new additive manufacturing-based approaches to customized nerve repair provide proof of concept that patients with peripheral nerve injuries one day could be brought into an emergency room, have the injured area scanned, and a custom nerve pathway created in under one hour. In cases of severe injury and extensive tissue loss, hospitals could refer to an electronic library of scanned nerve structures to match closely to fit a patient’s injury.

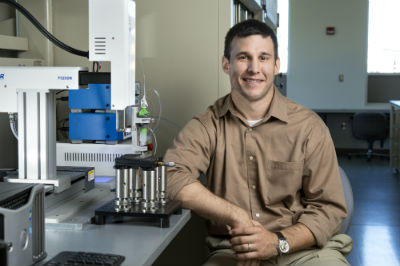

Johnson started at Virginia Tech in June 2015 as an assistant professor, following two years as a postdoctoral associate at Princeton. There, he won an Innovation Award for his research in additive bio-manufacturing. Prior to that, he earned his doctoral degree from Drexel University in 2013, and his bachelor’s degree from the University of Wisconsin-Madison in 2008, both in chemical engineering.